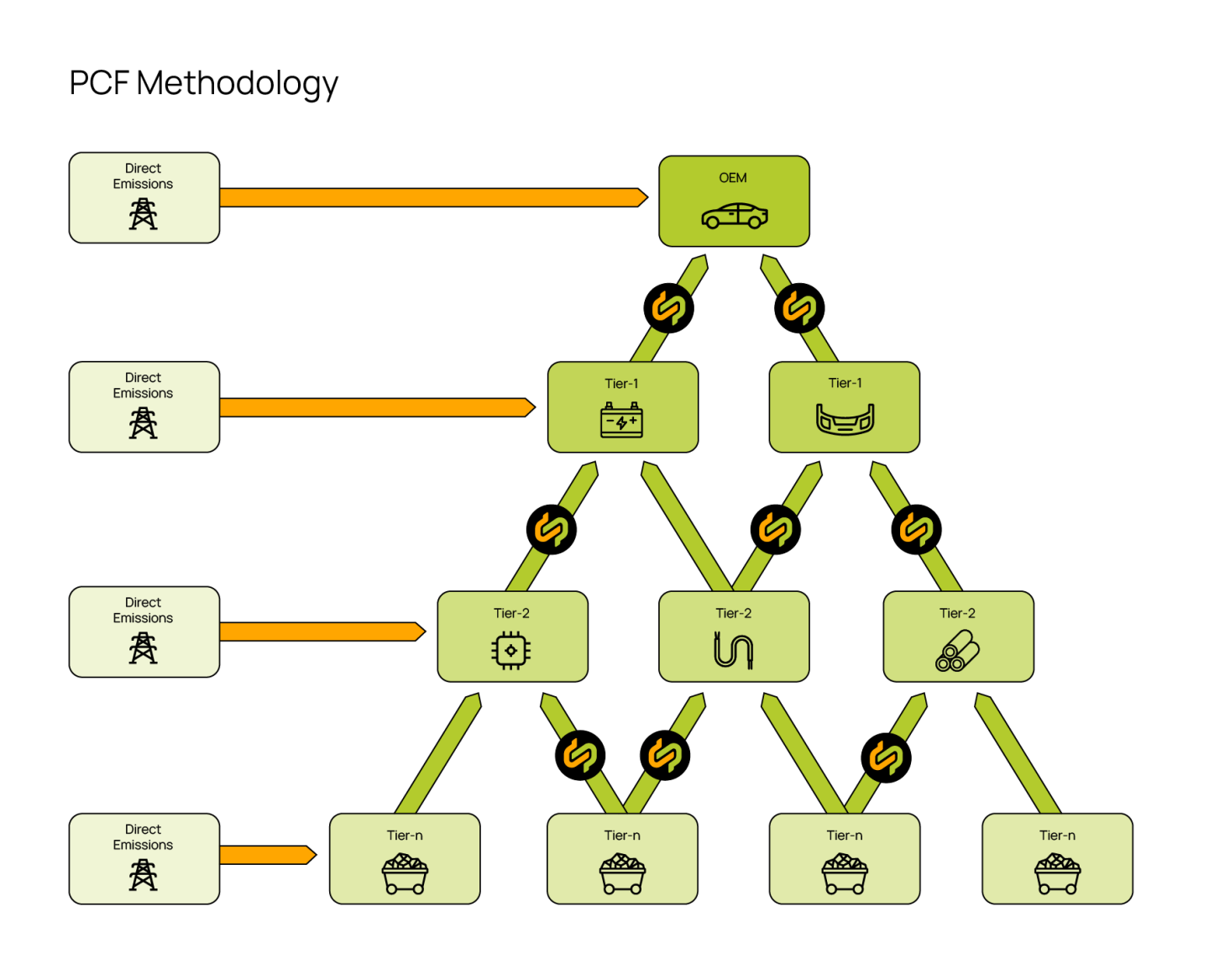

The Background: Fragmentation and Lack of Primary Data

Calculating the Product Carbon Footprint (PCF) of automotive parts is often based on industry averages and assumptions due to missing primary data from supply chains. Multi-tier supplier structures, lack of a common defined methodology of calculation and often use a variety of non-compatible tools – resulting in isolated solutions. Each partner has to choose between investing heavily in custom integrations or accepting limited data quality.

The result: inaccurate PCF calculations, limited reduction potential, and duplicated efforts throughout the value chain.