Quality is everyone’s business

Modern automobiles are becoming increasingly complex. New functions like autonomous driving mean the increased interlinking of components and control units. Catena-X is now also linking quality work – to achieve greater precision in less time.

With click on the following video, you will understand how we collaboratively identify quality issues at Catena-X. Please activate the English subtitles in the video:

Costly ‘parts tourism’

In quality management, data exchange has so far been very limited. Only when repairs are carried out in the workshop are problems revealed in the field. The basis of today’s quality work is thus the physical examination of damaged parts, called ‘parts tourism’. It is tedious and time-consuming for both automotive manufacturers and suppliers alike.

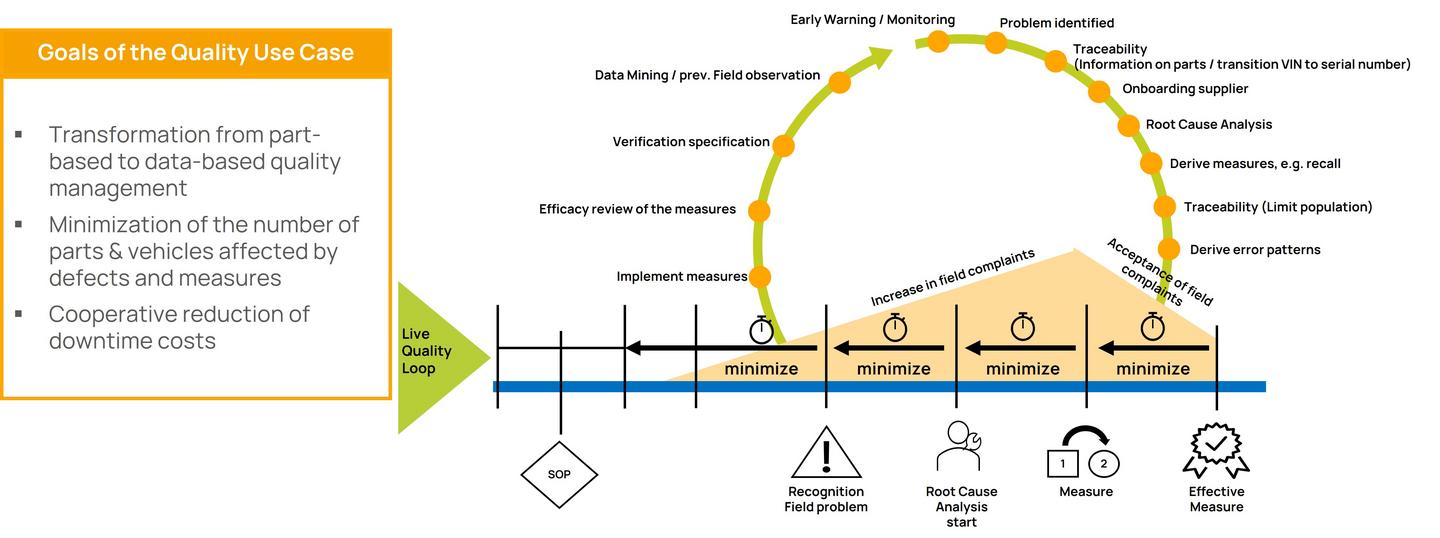

Consistent quality management

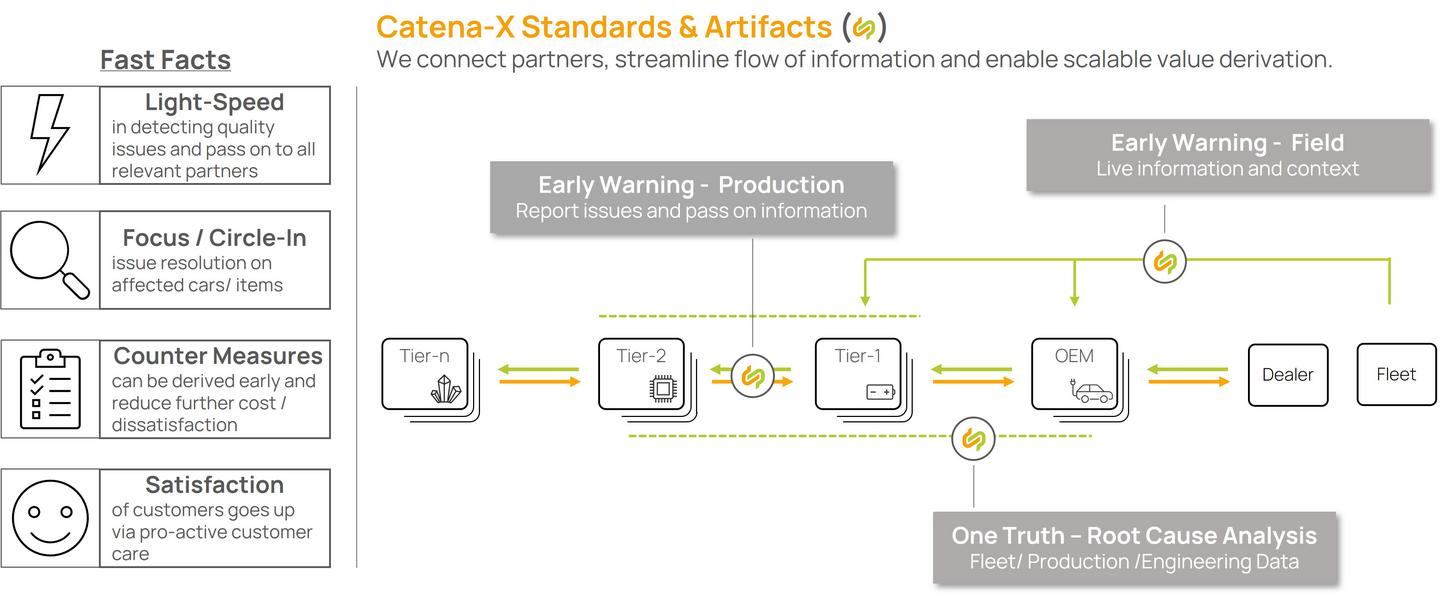

In the Catena-X network, we exchange data across company boundaries on a daily basis, securely and simply. Here, we combine field quality data from automotive manufacturers with production data from suppliers. This means a new level of transparency and collaboration for quality work: The continuous data chains allow a focus on early warning and monitoring of countermeasures while at the same time ensuring secure, sovereign data exchange. Even information about production changes, such as new manufacturing parameters, is included. However, sensitive, company-internal data does remain protected against access by unauthorised people.

Our collaborative approach is improving the work of the future:

- Data-based quality management means reduced costs compared to the parts tourism that still prevails.

- The fact that measures can be derived more quickly reinforces the effectiveness.

- Early warning systems in production and the field immediately identify defective components and vehicles.

- Root cause analysis and collaborative data evaluation reduce downtime costs.

In combination with the ‘traceability’ use case, we also enable greater availability of mobility for end customers. Because we combine detection with prevention and thus increase overall quality through the interplay of the two approaches.

Useful for SMEs, too

Quality management is also vital for small and medium-sized enterprises (SMEs). They depend on customer satisfaction and a good reputation. As a result, a transparent exchange of information with their business partners is even more critical. The Catena-X solution benefits both: a lower error rate due to targeted quality analyses and fast coordination through simple communication within the network.

Technical features

Our quality management is based on continuous data chains. These are created by digitally recording your company’s process and parts lists. Interrelated work steps are then linked together in the Catena-X data ecosystem. Individual components and materials can be fully traced this way.

The current state of development

The elementary building blocks for real use are available: freely selectable quality applications, uniform data models, and secure data exchange in the network. Our three software applications support the data-based early detection of quality problems and their root cause analysis. We have also standardised six semantic data models, which serve as your sole sources of information. That means you simply select the right system from the list certified by Catena-X.

You will probably be able to use our methods and tools productively from mid-2023: introducing and implementing Catena-X.

Christoph Marquardt

Product Owner

An Overview of Quality

Get an overview of how Catena-X is transferring quality management from part-based to data-based in order to make it faster, easier and more precise: