Efficiency in the flow of materials

The flow of materials is one basis for successful added value creation. Catena-X wants to stabilise manufacturing and delivery processes and so ensure greater efficiency for everyone involved with the aid of predictive online control and simulation.

Planning versus reality

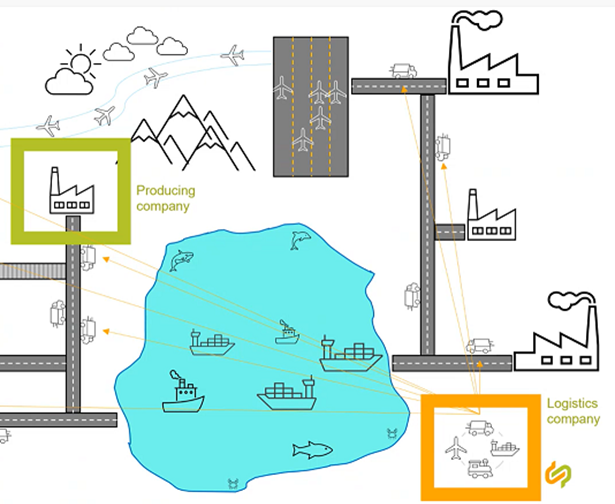

A product’s material flow includes several different stages:

- the extraction of raw materials,

- processing, storage, and transport within a company,

- forwarding to the next company,

- repetition up to the final delivery of the end-product to the consumer.

These individual stations are interdependent: Tier z can only keep to its plans if tier x delivers to tier y on time. This makes it even more of a challenge that internal and external influencing factors also have an effect in each case.

Companies generally take steps to prevent the corresponding risks, whether these be a shortage of staff, loss of material or a production stop: They outline scenarios and short-term remedies based on experience and reference values. Nevertheless, the last few years especially have demonstrated that reality can trump the plan.

Predictive software application

Catena-X is dedicated to forecasting manufacturing and delivery processes for the first time in the online control and simulation application case. This calls for modern simulation technology combined with artificial intelligence. The result is reliable data showing which planning is valid and where companies involved in value creation need to improve.

Advantages for everyone involved

The core of the Catena-X approach is the targeted exchange of results with one another. As soon as a discrepancy is identified, the parties involved are called upon to explain the dimensions transparently.

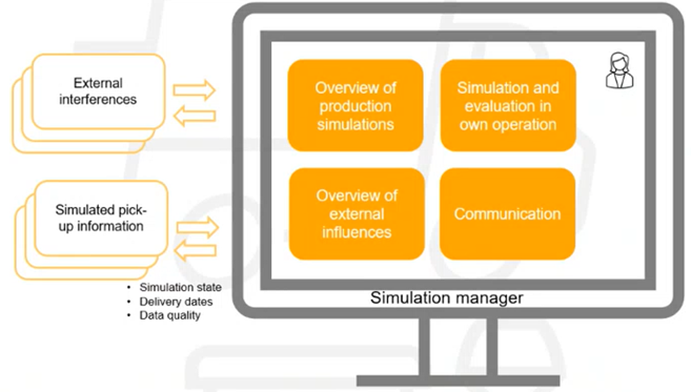

Therefore, communication with each other is part of the three software functions:

- As central application, the simulation manager provides access to the collaborative simulation model.

- The evaluations of the simulation results of the higher tier levels are clearly displayed on the start page.

- One’s own simulation results can be shared with suppliers, production and logistics companies involved in the value stream at short notice, and appropriate recommended precautions can be taken.

Useful for SMEs, too

Companies already active in the Catena-X ecosystem, just like any newcomers, can use the simulations themselves. The data evaluation is carried out either according to standardised specifications or with the help of an in-house simulation model; data import is performed manually or via standardised connectors. This also allows fewer digitised partners to participate in the network so that in the future, even many SMEs with less experience, expertise and available tools can benefit from the added value of the Catena-X ecosystem and make sure of their added value while covering costs and taking risks!

Let's start your Online Control and Simulation!

Theodor Isinger

Product Owner

Marc Kujath

Co-Lead