Manufacturing as a Service

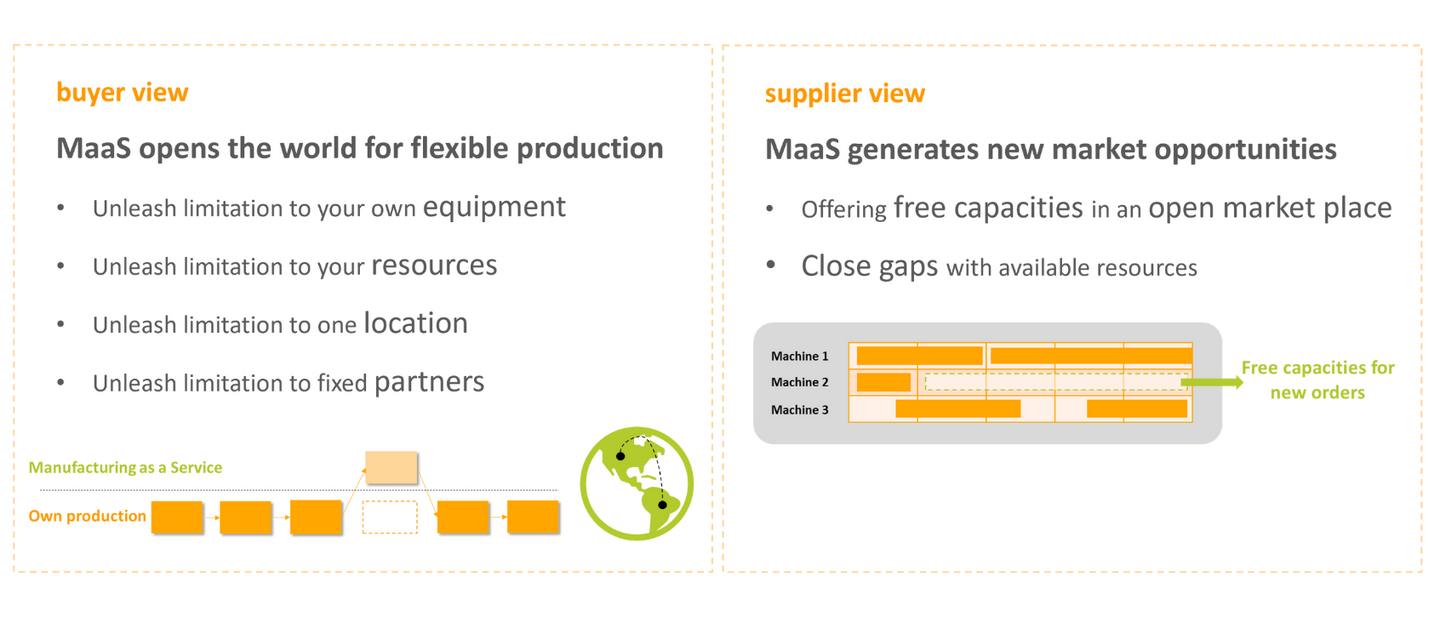

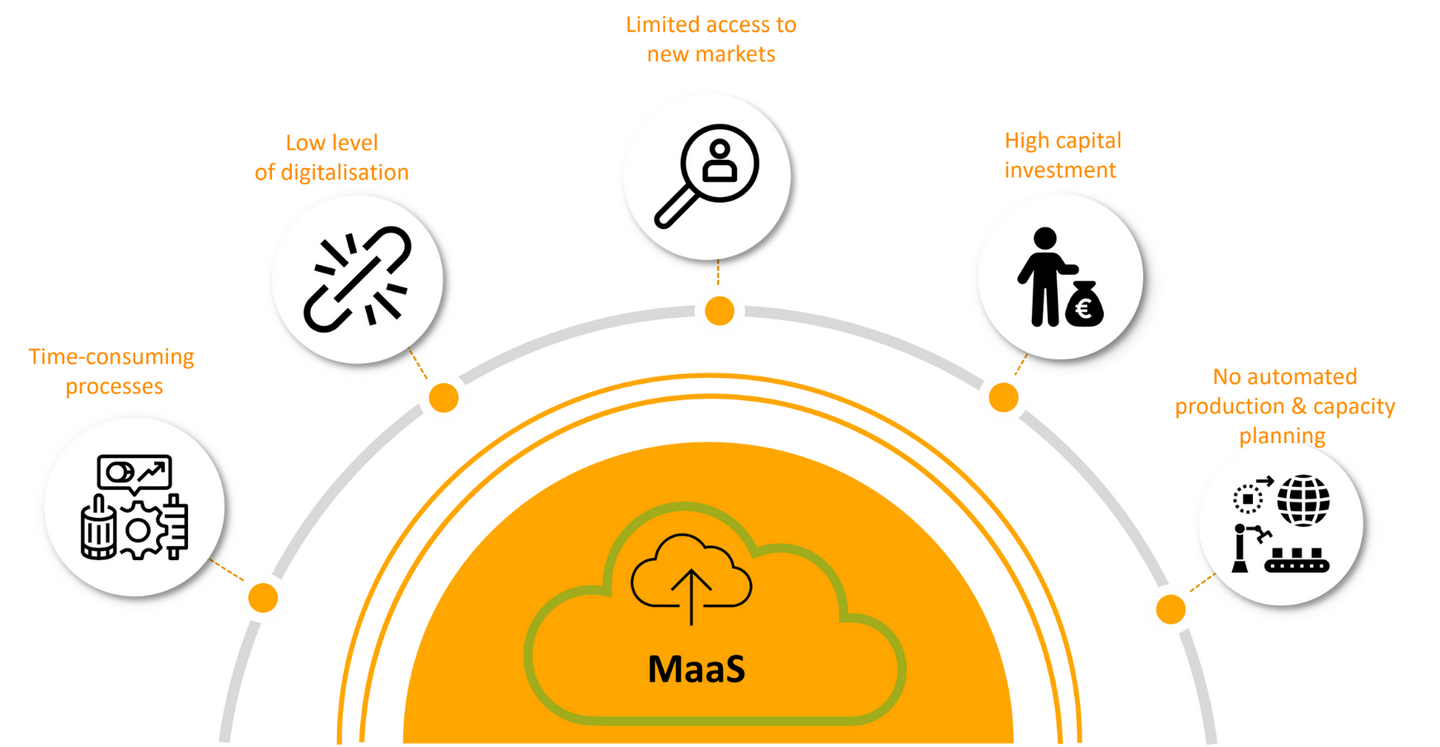

Manufacturing steps as a service — a paradigm shift to reduce capital commitment and to use free capacities and resources. The Catena-X data ecosystem brings prospective customers, suppliers and on-demand manufacturing platforms together for profitable interaction.

Short-term rescheduling

Material backlogs, delivery bottlenecks or technical defects occur over and over again in the industry. That is why most companies have contingency plans that describe what needs to be done and when. However, a quick remedy must be found if the customer order does not allow any delays. Numerous production sites offer their services as individual processes, known as “Manufacturing as a Service”, or MaaS for short.

If required, a company does not need to request a finished product, but it can request support for special work steps. The collaboration has advantages for both parties: The company receiving the request gains new orders, while the client can maintain its production.

International and cross-industry

With its MaaS applications, Catena-X wants to further expand this service aspect: Tier-n and Tier-1 businesses, as well as OEMs can register online and offer or request manufacturing processes, resources or even availability. In this way, they are not only providing their manufacturing services for known business partners but also to an international, cross-industry network.

Advantages for everyone involved

The Catena-X MaaS architecture uses open IT standards instead of depending on one platform provider. Anyone who notices under- or overproduction enters the demand or performance directly into the system. The algorithms stored orchestrate the information and, if required, initiate a comparison within the network for information on jobs and workpieces.

Order information

- Who is the customer?

- What are the details of the order?

- What are the pricing requirements?

- Which quantities are required?

- What is the time horizon?

Workpiece information

- What geometries are required?

- What are the material requirements?

- Which work steps are necessary?

- Which characteristics must be met?

- What are the quality guidelines?

If the information matches, the providers connected can work out their offers. The client is shown the potential service providers available and can make a selection at short notice. In terms of performance, quality and price, the alternatives are comparable.

Useful for SMEs, too

Catena-X networks all the operators involved in the value chain and explicitly addresses small and medium-sized enterprises (SMEs) with the MaaS solution. For them, under- and overproduction often give rise to existential fears. Both situations tie up the capital (which SMEs sometimes lack) needed to pay employee salaries and to cover other fixed costs. Interaction with the global manufacturing network lowers this risk and, in the best case, provides them with many new orders.

Technical features

Catena-X plans to standardise all interfaces and data models in the MaaS applications and to automate individual processes, for example from the offer to the conclusion of the contract to invoicing via:

- geometry analysis of 3D models

- calculations (instant quoting)

- integrated offer and order management

- production planning functions like master data management.

For the parties involved, this means a significant simplification of the connection while maintaining data sovereignty. Because despite the increased transparency, the manufacturing expertise remains within the company concerned.

Current state of development

Catena-X wants MaaS applications confirmed with selected partners by 2024. Will your company be one of them?